Introduction

Millipore Sigma is transforming life sciences with digital process twins—a data-driven approach to experiment design. This innovative methodology optimizes workflows, enhances reproducibility, and fosters collaboration, driving faster and more-impactful scientific discoveries.

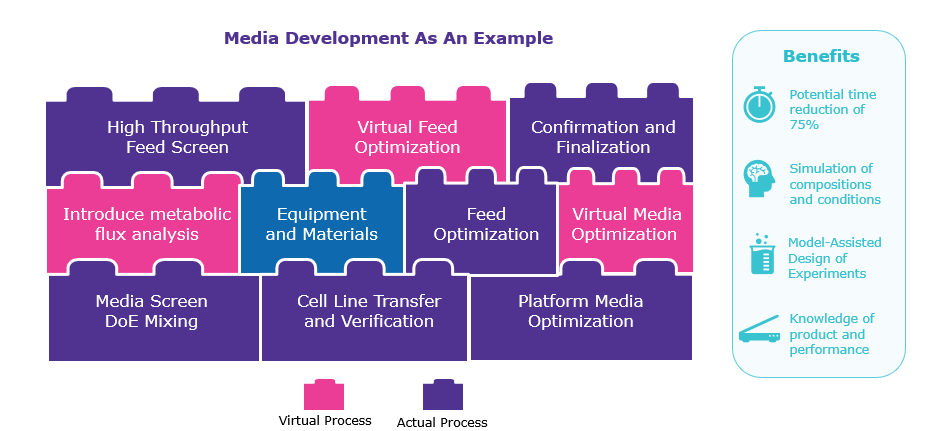

- Accelerates experimental timescales by up to 75%.

- Enhances data quality with enriched metadata and real-time monitoring.

- Drives collaboration and reproducibility through standardized processes.

About Millipore Sigma

Millipore Sigma, the U.S. and Canadian life sciences business of Merck in Darmstadt, Germany, is a leader in providing innovative technologies for scientific research and pharmaceutical development. Focused on empowering researchers to achieve breakthroughs, Millipore Sigma addresses complex challenges through advanced materials, comprehensive data solutions, and a customer-centric approach, shaping the future of health and innovation.

Reimagining experiment design for a data-driven future

For many years, experiment design has relied on manual, fragmented processes and isolated individual steps, leading to inefficiencies, variability, and missed opportunities for optimization. This way of working tends to create challenges such as incomplete data capture, experimental inconsistencies, and difficulty replicating results.

For example, environmental variables, such as temperature fluctuations caused by sunlight entering the lab at different times of the day, can introduce unwanted variability, making outcomes less reliable even as the cause can be very difficult to pinpoint. Additionally, the manual nature of experiment design often meant that valuable metadata—such as exact timings and conditions—were either not recorded or inconsistently documented. Reproducibility, a cornerstone of scientific research, was frequently compromised, slowing down the pace of discovery.

To add to this mix, collaboration across distributed teams produces another layer of complexity. Without standardized workflows and formats to share data, teams would struggle to compare results, reducing the opportunity to build on each other’s work.

Quote from David Nogales

Our experiments involve multiple interactions and touchpoints. To advance science effectively, we want to reimagine the process and eliminate inefficiencies that hold researchers back.

Digital process twins: A paradigm shift in scientific workflows

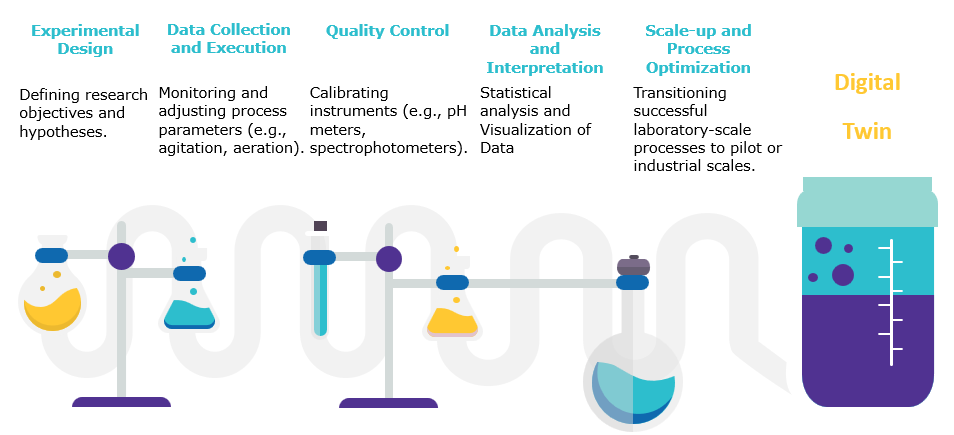

To reimagine its experiment design workflows, Millipore Sigma is adopting an innovative approach centered on the concept of digital process twins. Unlike traditional digital twins, which focus on replicating single pieces of equipment, digital process twins model entire experimental systems—capturing complex interactions and workflows in dynamic, data-rich representations.

This approach begins with a library of modular building blocks, each containing detailed metadata and instructions for specific experimental steps, such as pipetting, mixing, or analyzing samples. By dragging and dropping these blocks into digital workflows, researchers can design experiments that are both precise and reproducible. These workflows are seamlessly integrated into electronic lab notebooks (ELNs) such as Revvity Signals Notebook, streamlining execution and ensuring consistent data capture. The advantage is that the ELN centralizes the building blocks of digital workflows into a single data repository, enabling the creation and maximal beneficial use of digital twins.

Quote from David Nogales

A digital process twin is more than just a static replica; it’s a dynamic model that mirrors the entire experimental process,” David Nogales explains. “It integrates data from equipment, environmental conditions, and human interactions, creating a comprehensive framework to analyze and refine our experiments.”

The digital twin framework incorporates real-time data monitoring and in-silico modeling. This enables researchers to simulate experiments virtually, identifying optimal conditions before physical execution. Early trials demonstrated that using digital process twins could reduce experimental timelines by up to 75%, accelerating discovery while conserving resources.

Environmental variables, such as temperature fluctuations or light exposure, which previously introduced unknown inconsistencies, can be included in the experiment design in machine-readable formats, and accounted for, analyzed, and mitigated, resulting in more reliable outcomes. For example, using digital process twin simulations can reveal how time-of-day differences impact results, prompting adjustments to experimental protocols to enhance reliability.

Furthermore, the digital process twin approach promotes collaboration and transparency. Distributed teams can share standardized workflows and replicate experiments with precision, helping to create a unified research ecosystem.

With its holistic integration of data, automation, and modeling, Millipore Sigma’s digital process twin framework redefines experiment design as a scalable, efficient, and collaborative endeavor.

Quote from David Nogales

By creating a shared foundation for experiment design, we’re enabling researchers across the globe to collaborate seamlessly and build on each other’s work.

Unleashing the potential of data-driven science

By adopting digital process twins, Millipore Sigma is transforming how research is conducted, delivering tangible benefits across efficiency, reliability, and collaboration.

By capturing enriched metadata and monitoring real-time variables, researchers gain unparalleled insights into experimental processes, enabling them to identify patterns, refine protocols, and consistently achieve high-quality results. In addition, using simulations accelerates the research cycle, allowing teams to optimize experiments prior to real-world execution, saving time and resources.

Conclusion

David Nogales concludes: “Digital process twins allow us to focus on science, not logistics. By providing a unified framework, we can reduce inefficiencies, enhance collaboration, and unlock new opportunities for discovery. This is the future of research.”

End-to-end workflow support across scientific disciplines.

The Standard for Chemical Drawing.

End-to-end Clinical Data Science Platform.