Introduction

FrieslandCampina, one of the largest dairy cooperatives in the world, has been producing dairy products for more than 150 years. The company is headquartered in the Netherlands and has branches in 30 countries. At the company’s research and development center, about 600 employees conduct a broad range of activities, including nutritional studies, product characterization, new product and packaging development, technical support, and pilot plant trials.

Two years ago, the company undertook a project to organize its laboratory data using an electronic laboratory notebook (ELN). They wanted to move from a fragmented, unstructured state to a centralized, standardized environment to drive efficiency in R&D. They chose the cloud-native Signals Notebook™ as their ELN solution.

With support from the Revvity Signals team, FrieslandCampina configured and implemented Signals Notebook. The company’s R&D scientists now have a user-friendly interface and a modern data management system that centralizes and standardizes information, improving data sharing and collaboration. The solution also streamlines data analysis, facilitated by the easy integration of Microsoft tools that are familiar to the organization’s scientists.

Fragmented, Spreadsheet-based Data

Before implementing Signals Notebook for its R&D center, data from FrieslandCampina’s labs was fragmented—stored in multiple files and spreadsheets. The company had centralized its R&D to one building in 2014 and installed Microsoft SharePoint to store research data. However, many files were still stored locally and difficult to retrieve. In addition, formats were not standardized, which made it difficult to collate and compare data.

Without a central location for experimental plans and data, scientists had to rely on cumbersome and unsecure methods of communication. To run a pilot plant experiment, for example, scientists would write a protocol in a text document and send it by email to the technicians who would run the trial. The scientists would wait for an email from the operators with the log-list and another email from the quality control (QC) lab with data. They would separately pull time series data about the pilot plant process from the historian. Once they collected all information in one place, they would put the data into Microsoft Excel to visualize and analyze it.

Centralized, Structured Data Management

With Signals Notebook, both experiment planning and results are stored in one place, streamlining information sharing and reducing the workload. For pilot plant experiments, connecting the process data historian allowed further automation of data-handling tasks. For example, the ELN data and process historian data can be used to automatically generate graphs in PowerBI. FrieslandCampina also connected their QC lab to Signals Notebook, allowing automatic addition of QC results to the ELN.

Signals Notebook has streamlined how experiments are run and provided a central storage location for research information. Information is now easier to retrieve and analyze.

Configuring and Implementing

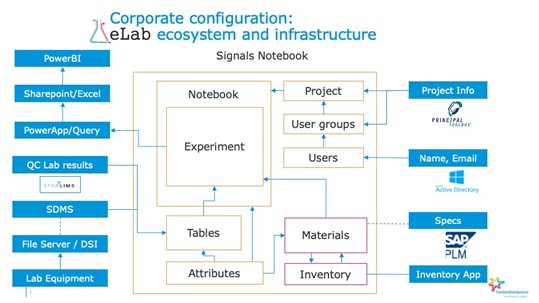

FrieslandCampina called their corporate configuration of the Signals Notebook “eLaborate” or eLab for short because the company wanted their scientists to have a better way to share more information about the experiments they are doing, in a structured manner that promotes consistency and enhances searchability. Signals Notebook offers this structured consistency with customized templates and a user-friendly interface.

The corporate team configured Signals Notebook to automatically bring user, project, equipment, and instrument information into the ELN from corporate systems. They also imported materials specification data from their existing SAP product lifecycle management (PLM) system and created an Inventory app in the ELN to facilitate entry of inventory information.

FrieslandCampina’s scientists rely on Microsoft tools, such as Excel, SharePoint, and Power BI, so the ability to continue to use these tools easily was important to the team. Because Signals Notebook offers native integration with Microsoft products, so users can, for example, open and edit an Excel spreadsheet within the ELN. The corporate team also configured eLab so all experiment and sample data could be easily extracted from Signals Notebook into these data processing and analysis tools, using PowerQuery.

After this initial configuration, Signals Notebook was launched across all R&D departments. The corporate team quickly realized, however, that the configuration needed to be further optimized for the varied needs of each department. The team took a step back to review processes, instruments, and systems. The subsequent rollout was performed at the department level, with each department determining the resources it needed and the best timing for implementation.

A governance structure was put in place at the department level, with designated unit and digital leaders facilitating the transition. In addition, super users were identified to simultaneously receive training and participate in configuration. Rather than the central team leading the configuration discussions, ownership was assigned to the digital leaders from the departments. The super users were encouraged to be positive and proactive, and to take what they learned and train other users in their department. This involvement helped address resistance to change. All users have now adopted eLab as a new way of working, and the eLab system is now being successfully employed, bringing structure to lab data in every department—facilitating cross-departmental collaboration.

Summary: Centralizing and Standardizing R&D Information

Signals Notebook from Revvity Signals—configured at FrieslandCampina as “eLab”—standardized data capture and brought structure to data from experiments, samples, methods, material libraries, and inventory, all stored within Signals Notebook. Because everything is now organized in one place and accessible to everyone, workflows are streamlined, and information is easier for scientists to search and use. R&D personnel are now able to more effectively communicate and collaborate. Smooth integration of familiar Microsoft tools and the addition of new, automated data management tools further reduce the scientists’ data-handling workload, enhancing productivity.

FrieslandCampina found that empowering the users in each department to participate in the configuration and rollout process was key to optimizing the ELN and bringing all its users on board. The company is now poised to drive even more efficiency and innovation in R&D.

Quote from Ruud Schoemaker

“We are moving from a fragmented, unstructured and non-standardized state to a centralized environment where our information [is] comprehensive, structured, and standardized.”

View more case studies at Revvity Signals.

End-to-end workflow support across scientific disciplines.

The Standard for Chemical Drawing.

End-to-end Clinical Data Science Platform.